Interreg-Project UP STRAW

UP STRAW was the largest EU-funded project to increase the use of straw in the construction sector ever, and it was a success! Read more about the project targets, the activites and people involved below or click here to see the results immediately: LINK

Introduction

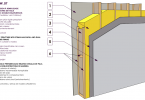

Creating a healthy and comCreating a healthy and comfortable inner climate in buildings and reducing CO2 can go hand-in-hand! Building with straw, in combination with clay, has this effect. CO2 reduction takes place by using optimal insulation and by the CO2 contained in the natural material straw itself. The use of straw and clay create a healthy inner climate.

SStraw is widely available and can be applied in new constructions (houses, offices, schools, public buildings). Straw is also applicable for the insulation of existing buildings. Straw can be used immediately from the production location (farmland), without a further processing.

This makes straw a premium biobased building material.

UP STRAW: A collaborative approach to creating straw awareness and usage

Heating all of the buildings in North West Europe accounts for about 15% of the GHG emissions. The use of straw as building insulation helps to reduce the emissions in a natural way. During the project we demonstrated how to reduce emissions in five public building projects: buildings made of bales, wrapped in straw and created with prefab straw panels.

Training programmes for 2,000 architects, constructors and straw craftsman facilitated knowledge development. University modular programme elements made students aware of how to use and specify straw as an insulation material.

Implementation of straw elements in building methodology and Building Information Modelling software will facilitate the use of straw elements in the building industry.

Communicating the advantages, application and the effects of building with straw will create awareness and interest in the possibilities and application. The image of straw as a building material will significantly improve.

Duration: 42 months, Start date: March 2017, End date: December 2021

Budget:

The total budget is 7 050 600 Euro. The European Union finances the project to 60%, other partners must be found to finance the remaining 40%.

Lead partner:

| Organisation | Address | Website | |

|---|---|---|---|

| Centre National de la Construction en Paille | 69 bis rue des Déportés et des Internés Montargis 45200 France | stephanie.ventre@cncp-feuillette.fr | www.cncp-feuillette.fr |

Partner organisations:

| Name | Contact Name | Country | |

|---|---|---|---|

| Cluster Eco-construction | Hervé-Jacques Poskin | hj@ecoconstruction.be | Belgium |

| Strobouw Nederland | Wouter Klijn | wouter@strobouw.nl | Netherlands |

| Gemeente Tilburg | Maikell Van Rooijnen | maikell.van.rooijen@tilburg.nl | Netherlands |

| The School of Natural Building | Eileen Sutherland | eileen@schoolofnaturalbuilding.co.uk | United Kingdom |

| Hastings Borough Council | Murray Davidson | MDavidson@hastings.gov.uk | United Kingdom |

| Plankstetten Benedictine Abbey | Benedikt Kaesberg | info@bau-mit-stroh.de | Germany |

Project Summary:

Heating all of the buildings in NWE accounts for about 15% of the GHG emissions. New passive buildings and large scale renovation are needed to reduce these emissions, and construction emissions themselves account for about 12% of GHG (cement, bricks, glass and petrochemicals – source EEA).

The aim is to reach 5% of the construction market in 2030 and to save 2 MT CO2 (incl. fixed CO2).

The challenge is to improve the insulation of buildings with natural materials which have fixed carbon during their life cycle. Wood is now well known. Straw has impressive insulation characteristics, too, but is still to be better known and promoted in order to be used on a large scale.

Straw bales are available all over the territory (millions of tonnes in every country). It is typically the widespread cheap sub-product of the agricultural sector, local and biodegradable: a perfect illustration of circular economy.

Actions:

- We created Technical tools that help professionals to know how to use straw and to prescribe it (BIM, ETA, carbon balance, straw building device).

- We developed a MOOC and other training programmes for students, architects, engineers, and builders for using straw in their projects.

- We elaborated a market development strategy for boosting demand and SMEs’ ability to serve this demand.

- We validated straw insulation techniques for retrofitting existing buildings.

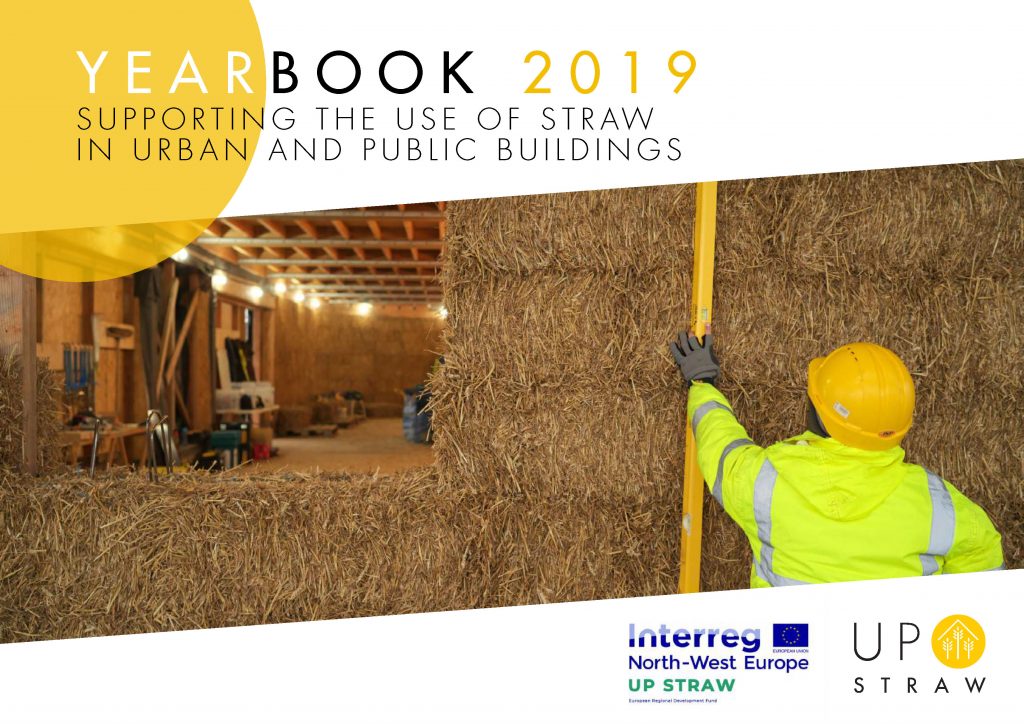

- We implemented a great number of communication measures: information material, podcasts and videos, fairs, site visites, open conferences (including the European Straw Bale Gathering 2019) – link and publications which all helped to improve the image and growing awareness of straw as a construction material..

Around thirty sub-actions are associated with the main actions.

The long term effects will be a major change in the perception of straw as a building material thanks to training programmes and appropriate demonstration and communication. The project also brought tangible solutions to actual challenges like terms of reference for public procurement, specifications for straw in BIM (Building Information Modelling) or life cycle assessment for straw and guarantee system.

ESBA is supporting the long term results of the UP STRAW actions.

Yearbooks 2018-2021

Contact:

Manager UP Straw : Stephanie Ventre

CNCP-Feuillette (Lead Partner) stephanie.ventre@cncp-feuillette.fr

More Info: www.nweurope.eu/upstraw